SPARTUS Easy 2000 laser welding machine with double wire feeder

Out of stock in the main warehouse, does not take into account distributor's stock levels

Notify me about availability

The set includes:

- laser source Raycus

- F230 handheld laser head (9,5m) with F150 focus lens

(as an option, there's the possibility to switch the F210 head) - double wire feeder with 4 wire guide rollers 1.2 - 1.6V fi37

- distilled water or coolant – selection depending on the season

- single insulated steel liner

- double insulated steel liner

- 2 wire guide rollers 0.8 - 1.0V fi37

- 4 wire guide rollers 2.0 -2.5V fi37

- head support for double liner

- 6 double welding nozzles

- 3 double wire feeder tip

- set of single nozzles for the laser head

- 4 single wire feeder tips

- protective lenses

Variants

Product description

SPARTUS® EASY 2000 – INNOVATIVE TECHNOLOGY FOR WELDING, CUTTING AND CLEANING MATERIALS

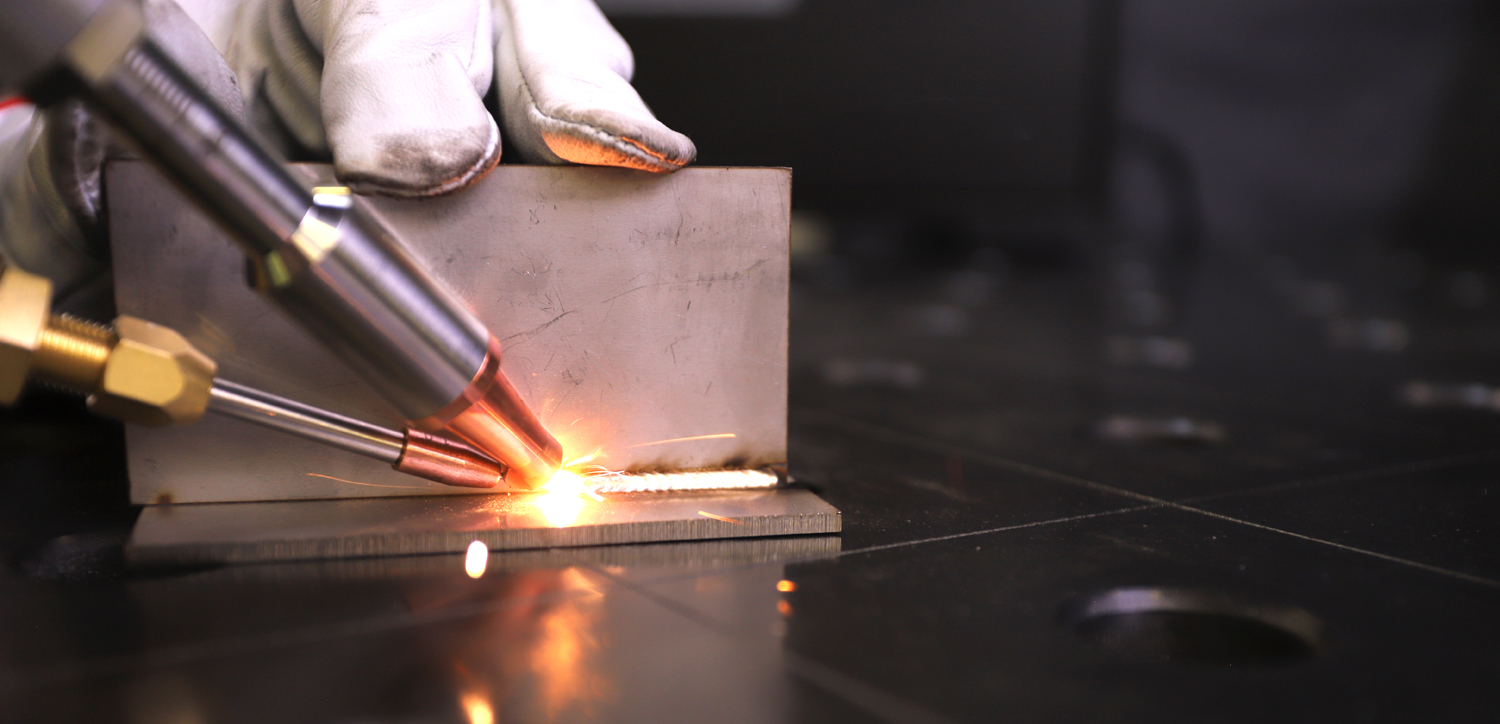

The SPARTUS® Easy 2000 laser welder is the key to achieving unparalleled quality in connections. This device surpasses traditional welding methods like MIG or TIG due to the exceptional precision it offers. The laser enables the creation of significantly smaller, microscopic-sized welds, thereby minimizing the heat-affected zone on the surrounding material. Consequently, laser welding is an excellent choice for joining even the tiniest components that are challenging to weld using other welding methods.

ADVANTAGES OF SPARTUS® Easy 2000:

- High precision welding

- Excellent control over the welding process

- Limited material distortion

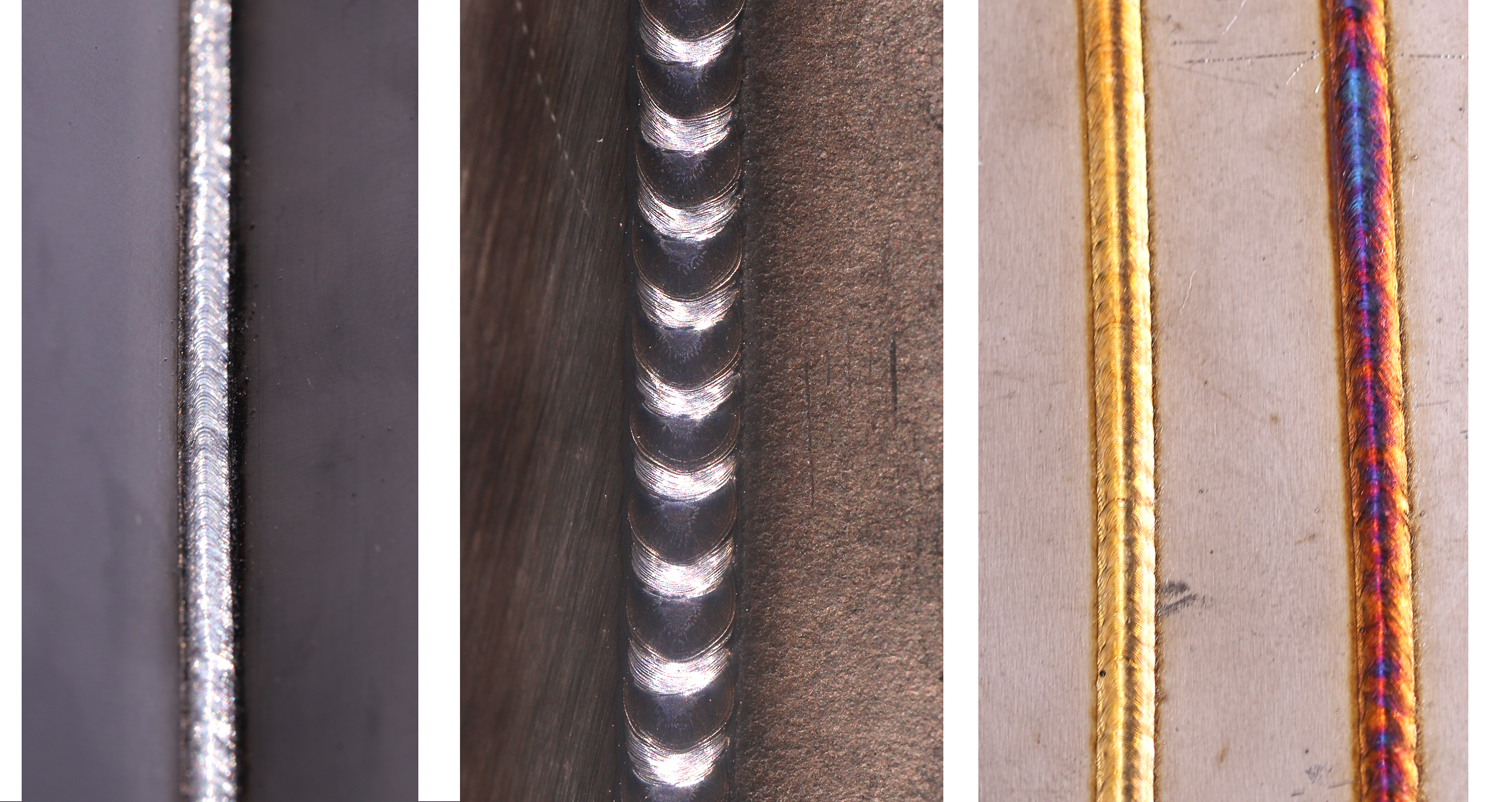

- Clean welds that require no post-processing

- Application in hard-to-reach areas

- Optimized production time

- Durable and resilient joints

- Capability to join, cut, and clean various materials

- High-class laser source

WIRE FEEDER

The SPARTUS® Dual Wire Feeder has been designed to enhance efficiency and quality in the welding processes within the most demanding industrial environments. Thanks to its innovative design that allows the use two welding wires, this feeder is the ideal solution for Easy laser welders, offering a range of benefits to its users.

- INCREASED PRODUCTIVITY The dual wire feeder reduces downtime associated with spool changes, contributing to faster and more efficient production cycles.

- VERSATILITY The dual wire feeder allows for quick adaptation to changing design requirements.

- PROCESS OPTIMIZATION Users can easily switch between wires of different diameters or properties to tailor the welding process to specific tasks, ensuring high-quality welds and work efficiency.

- IMPROVED WELD QUALITY Thanks to the ability to use dual wire for the welded material, the SPARTUS® feeder ensures better alignment in larger gaps, resulting in more durable and aesthetically pleasing welds.

- OPERATIONAL COST REDUCTION Long-term benefits such as reduced downtime and improved work efficiency lead to significant savings.

WELDING MATERIALS

| Butt welding (maximum thickness) |

| 6.5mm 5mm 6mm 6mm 5mm 3mm |

SPARTUS® LASER HEAD F230

The modern laser head allows for focal length adjustment. Additionally, it is equipped with a welding wire feeder mechanism. Ergonomic and user-friendly, it ensures precise and comfortable operation for the operator. Comes with a set of starter nozzles.

As an option, there's the possibility to switch the F210 head.

ONE DEVICE, MULTIPLE FUNCTIONS

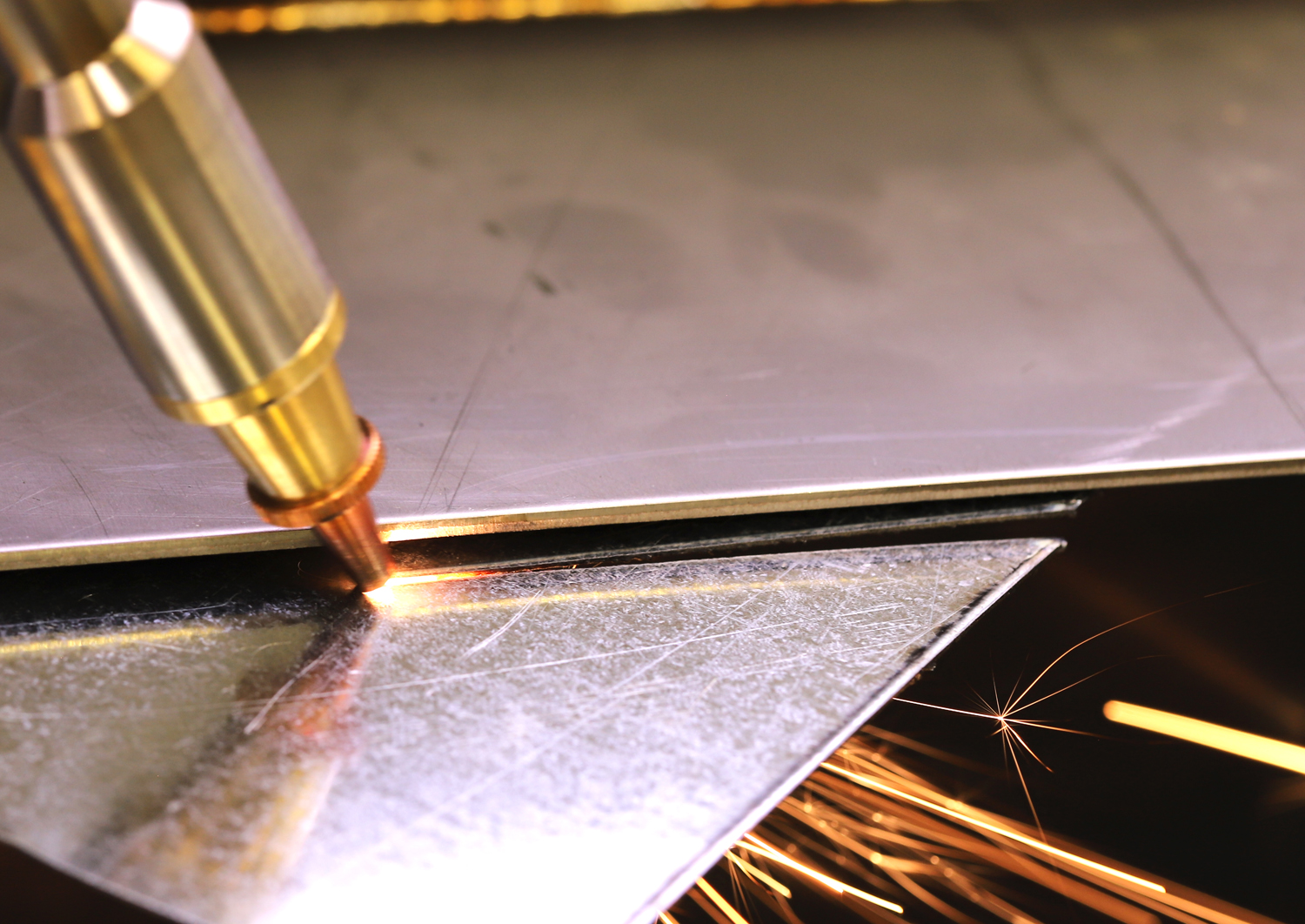

SPARTUS® Easy 2000 is not only used for welding but also for cutting and cleaning various materials.

Laser cutting allows for precise material separation, creating accurate and clean edges without the need for mechanical processing. The cutting function as an additional device option allows cutting stainless steel up to 2mm and carbon steel up to 1.5mm. Copper and aluminum, as materials with a high beam reflection coefficient, should not be subjected to the laser cutting process.

Laser cleaning is an effective method for removing contaminants, paint layers, or rust from material surfaces while preserving their integrity and quality. Thanks to these laser technology applications, we achieve exceptional material processing efficiency with minimal impact on their structure.

MULTILINGUAL MENU

The device interface is available in the following languages: • Polish • English • German • French • Spanish • Italian • Czech • Slovak • Greek • Romanian • Portuguese • Korean • Turkish • Russian

Technical details

| Input | ~1× 230V ± 10% 50 / 60 Hz |

| Output power | 2000W |

| Operating mode | continuous / modulation |

| Cooling type | liquid |

| Duty cycle | 100% |

| Scanning speed | 2 - 6000 mm/s |

| Scanning width | 0 - 8 mm |

| Frequency | 5 - 5000 Hz |

| Weight | 165kg |

| Dimensions | 956 × 580 × 823 mm |

Media

Files to download

- Others

- Parts diagram for SPARTUS® laser welder

File size: 685 KB

- SPARTUS laser welding and cleaning machines_EN.pdf

File size: 9 MB

-

![LaserBOX - head parts kit [double wire feeder] LaserBOX - head parts kit [double wire feeder]](https://novweld24.pl/upload/default/thumbs/b2b/product_list/images/product-images/spbox7-laser-20/spbox7-laser-20_1.jpg)

![Focus lens D20 x 4.5 F150 [welding, cutting, cleaning up to 30mm] Focus lens D20 x 4.5 F150 [welding, cutting, cleaning up to 30mm]](https://novweld24.pl/upload/default/thumbs/b2b/product_list/images/product-images/sp050-11-002/sp050-11-002_a01-2.jpg)