ProMIG 200PFC configurator

Available

The Pro machine configurator allows you to create a custom package.

BASE contains: ProMIG200PFC source

In the other dictionaries, you can configure the remaining equipment options.

Variants

Product description

ProMIG 200PFC – TECHNOLOGICALLY ADVANCED, PORTABLE, SYNERGIC MIG 3IN1

SPARTUS® ProMIG 200PFC is a professional, portable, multi-process semi-automatic welding device. It enables MIG/MAG, TIG and MMA welding with maximum welding current of 200A. The unit is powered from a single-phase network 230V.

TECHNOLOGICALLY ADVANCED WITH MULTILINGUAL MENU

The machine was produced with using of modern solutions such as inverter technology, IGBT power transistors, MCU controller, PWM technology, PFC filter. All of our technology solutions provide stable output performance under a variety of conditions, which has a direct effect on outstanding arc characteristics and welded joint quality.

ProMIG 200PFC is equipped with a high-resolution digital color LCD display with an intuitive user interface. It has been programmed for maximum convenience when setting parameters. The undoubted advantage is the multilingual interface, available in languages: Polish, English, Spanish, German, French, Russian, Slovenian, Portuguese, Lithuanian, Serbian and Czech.

VERSATILE – 3IN1 MACHINE

MIG WELDING

16 synergistic programes

ProMIG 200PFC is equipped with 16 ready-made, synergistic programs for welding such materials as: steel, stainless steel, aluminum and CuSi3 brazing program. The user only selects the type of material to be welded and the diameter of the wire. Then, after setting the material thickness, the parameters adjust automatically. Additionally, it allows you to manually correct parameters.

The machine has a number of functions that support MIG / MAG welding processes:

- Wave Control – precise arc dynamics adjustment Wave control ensures full control over the welding arc: it allows to reduce the amount of welding splashes and controls the width and depth of fusion.

- Burn Back – precise adjustment of welding wire burning speed allows limit a risk of sticking the welding wire to the contact tip.

- Slow Feed –so called gentle start-up of the wire feeder, recommended especially during welding with high amperage and high speed of wire feed. Smooth start of wire feed eliminates the risk of welding defects at the beginning of the weld.

- 2T/4T – choice of one of two operating modes..

Manual mode

ProMIG 200PFC also works in manual mode. It allows you to set all welding parameters in accordance with the individual requirements of the user.

Spool Gun

ProMIG 200PFC gives possibility of welding with a Spool Gun type welding holder with a built-in wire feeder. This significantly relieves the device and increases its range, allowing you to work with welding guns longer than 5 meters.

Polarity change

External change of welding polarity enables welding with self-shielding wires without gas. Both with the use of a standard MIG / MAG gun as well as a SPOOL GUN.

Stable wire feeder

A high-quality, built-in two-roll feeder ensures stable welding wire feeding. Smooth movement during operation is essential in order to obtain a high-quality weld.

TIG Lift WELDING

ProMIG 200PFC enables welding with the TIG Lift method. Thanks to the built-in solenoid valve, the device allows the use of a TIG welding torch with a microswitch (proposed SPP17-4-mSRP1B-X-8SPA)

ProMIG 200PFC has a functions that support TIG welding process:

2T/4T operating modes

Down Slop

Post-gaz - gas flow after completion of welding

MMA WELDING

The device also allows for basic welding by the MMA method. Built-in functions to support this process include:

Hot Start – for easier electrode ignition

Arc Force – for easier welding in forced positions

VRD – lower no-load voltage, increased work safety.

MOBILE AND LIGHTWEIGHT

Compact size, lightweight and special design, make the ProMIG 200PFC extremely handy and easy to move. Perfect for professional renovation works in the field.

APPLICATION

SPARTUS® ProMIG 200PFC is made in accordance with the latest trends in the production of welding equipment. Compact size and technologically advanced solutions make this welding machine a perfect device for the shipbuilding industry to perform minor repairs and renovations. It is also used in widely understood workshop works, light production works and in the automotive industry - car body repairs: welding and CuSi3 brazing, welding of exhaust systems.

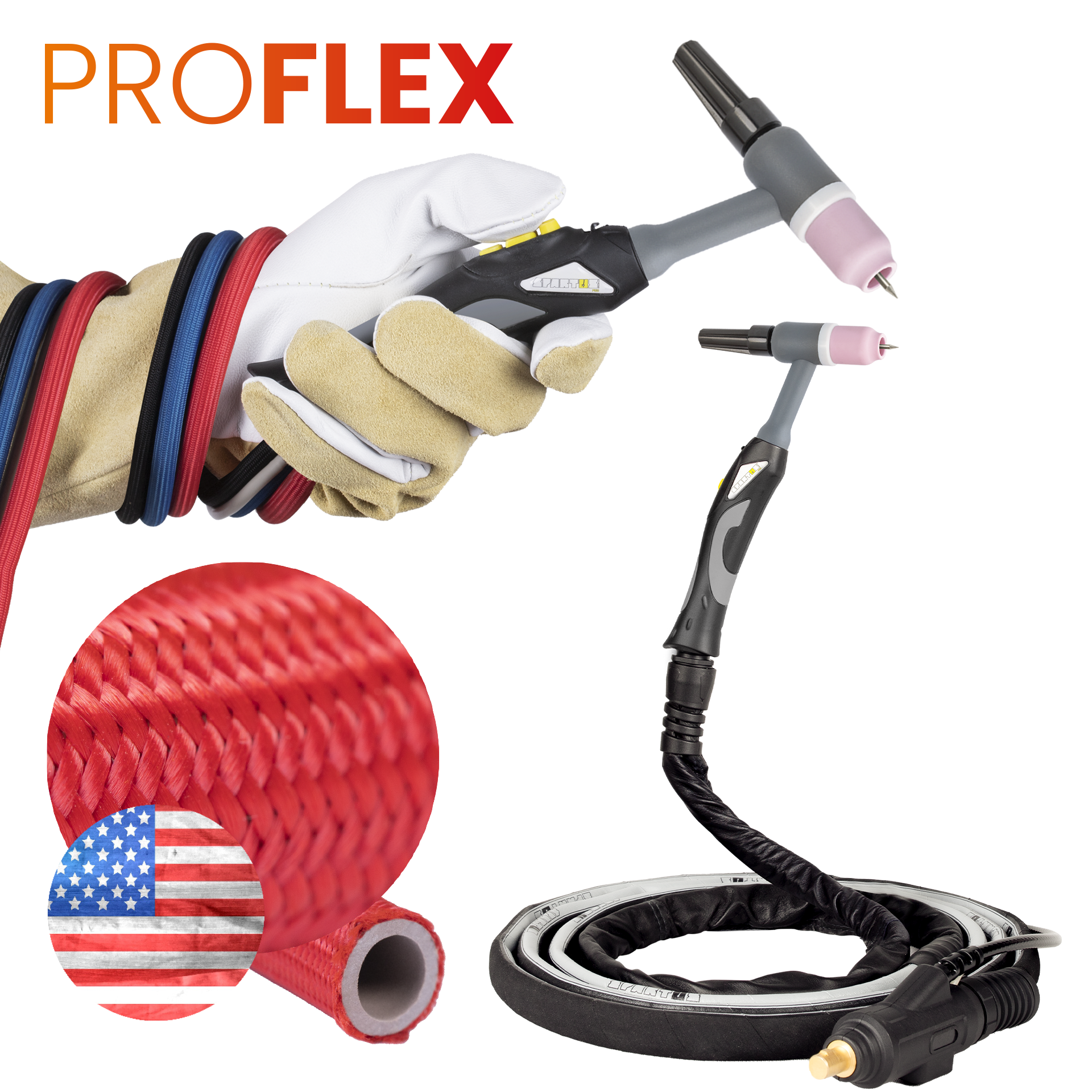

EQUIPMENT OPTIONS

SPARTUS® ProMIG 200PFC is available in 2 options: standard and package. Standard include source and basic wires (electrode holder, work clamp). An extensive package allows us to complete the device fully ready to work. Package, in addition to the source and MMA wires, is equipped with a high-class gun ProMIG 150 with rotary torch head. It is possible to create an extended package with the previously mentioned ProTIG SPP17 torch with TIG toolbox (consumable kit). It is a high-class Polish welding torch. ProTIG torch is made on American wires ProFlex, which retain a high level of flexibility at both high and low temperatures.

|  |  |

| MMA cables and gas hose | MIG gun SPARTUS® 150R with a rotary torch head | TIG torch SPARTUS® Pro 17 1B X |

In addition to the presented configurations, we additionally recommend compatible Spool Gun holders, gas regulators, foot controls and other SPARTUS® accessories.

Technical details

| Input | ~1× 230V ± 10% 50 / 60 Hz |

| MIG welding current | 25 - 200A |

| MIG duty cycle | 40% |

| Output working voltage | 15.3 - 24V |

| Wire feeder | built-in, 2-roll gear |

| Wire feeding speed | 1.5 - 13m/min |

| Welding wire spool | ≤ 5kg / ∅200mm |

| Wire diameter | 0.6 / 0.8 / 1.0mm |

| 2T/4T Control | yes |

| Additional MIG functions | Burn Back, brazing (CuSi3), Pre-gas, Post-gas, inductance control, spool gun, Slow Feed |

| TIG Lift | yes |

| TIG welding current | 10 - 200A |

| Down slope | 0 - 10s |

| MMA welding current | 10 - 200A |

| Arc Force | yes |

| Hot Start | yes |

| VRD | yes |

| Current consumpiton | MIG 25.4A / MMA 28.8A / TIG 20A |

| Power factor (cosφ) | 0.99 |

| Efficiency η | 85 |

| Insulation class | H |

| Protection class | IP21S |

| Weight | 16.4kg |

| Dimensions | 600 x 210 x 410mm |