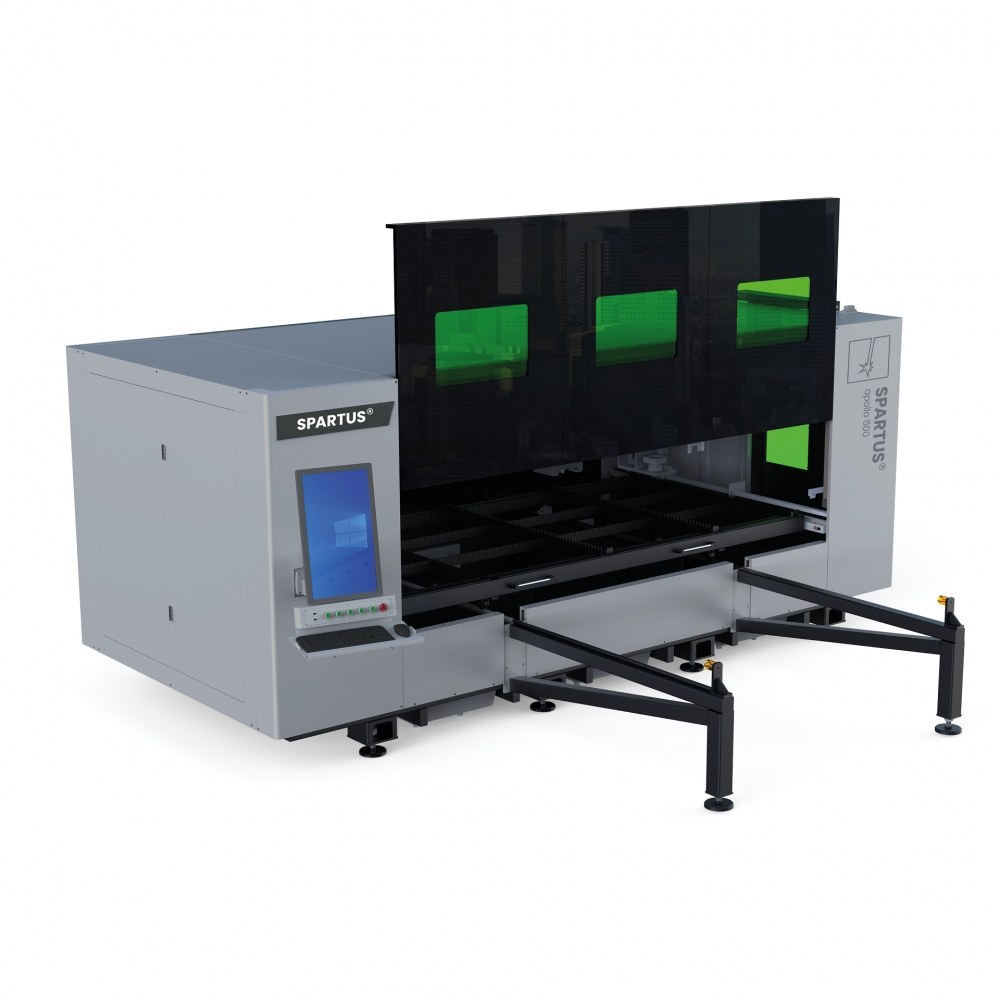

Spartus Apollo 500 laser cutting machine [3000W]

Available

Standard:

EN ISO 12100:2010

EN 60204-1:2018

EN ISO 11553-1:2020+A11:2020

Variants

Product description

SPARTUS APOLLO 500 LASER CUTTER – CUTTING PRECISION FOR MODERN PRODUCTION

CONCENTRATED POWER AND HIGH QUALITY

SPARTUS Apollo 500 is a modern fiber laser cutter with a power output of 3 kW, designed for precise sheet metal cutting. The integrated Raycus laser source and Raytools BM110 cutting head with autofocus ensure not only excellent cutting quality but also long service life and stable operation even under intensive production conditions.

COMPACT AND STABLE STRUCTURE

The Apollo 500 is built on a reinforced welded frame, precision-machined to the highest standards. Its gantry-style design with rack-and-pinion drive provides rigidity, vibration resistance, and excellent dynamics. The crossbeam made of cast aerospace-grade aluminum ensures durability and resistance to deformation.

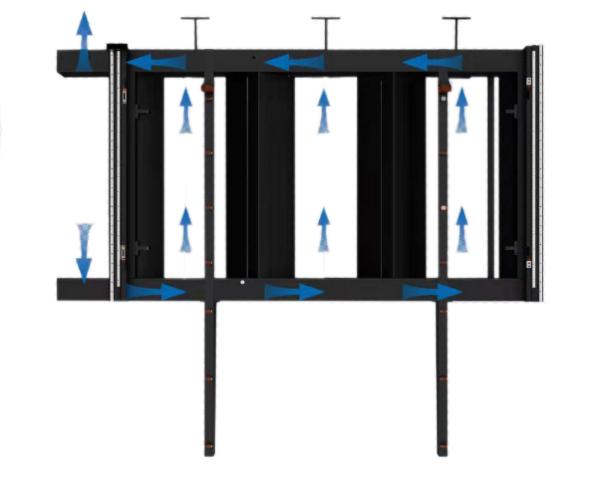

EFFICIENT EXTRACTION SYSTEM AND ENCLOSED HOUSING

The enclosed design features a zoned extraction system – air is blown in from one side and extracted from the other. This setup allows effective removal of smoke and dust directly from the cutting area, ensuring cleanliness, safety, and protection of optical components.

ADVANCED OPTICS FOR DEMANDING APPLICATIONS

Raytools BM110 is a cutting head designed for intensive use, featuring autofocus, advanced lens cooling, and four protective lenses.

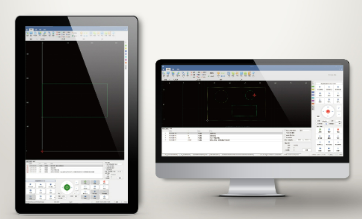

INTUITIVE CONTROL AND FULL MANAGEMENT

Raytools X3S is an industrial-grade control system offering full CAD/CAM/NEST integration. It enables automatic drawing error correction, cutting optimization, and advanced production planning. The 21” screen provides quick access to all functions, while built-in statistical tools and motion error compensation ensure repeatable results.

VOLTAGE STABILIZER – POWER SAFETY AND RELIABILITY

The SPARTUS Apollo 500 is equipped with a 40 kVA voltage stabilizer, which plays a key role in ensuring the machine's safe and stable operation. It automatically adjusts the power supply to local electrical conditions, regardless of the country or region. Voltage stabilization and regulation protect electronic systems from spikes and interference, increasing component durability and overall laser system reliability.

ENGINEERED FOR PERFORMANCE AND USER CONVENIENCE

The Apollo 500 is designed for ease of use: the working table with side-slide functionality allows convenient loading and unloading, while the built-in automatic lubrication system and visual monitoring support continuous operation. Electrical components from Schneider Electric, PEK guides, Atlanta racks, and Leitesen gear racks ensure high durability and reliability.

PERFECT CUTTING SAMPLES

The Apollo 500 excels in cutting thin-walled parts, sharp corners, and micro-holes. It delivers shiny and clean edges. This solution meets the needs of demanding industrial applications, where not only speed but also top-tier quality matter.

SPARTUS APOLLO 500 CUTTING PARAMETERS

| Material | Thickness [mm] | Cutting speed [m/min] | Laser power [W] | Gas | Pressure [bar] | Nozzle [mm] | Focus position [mm] | Cutting height [mm] |

|---|---|---|---|---|---|---|---|---|

| Carbon steel | 1 | 28-35 | 3000 | N₂/Air | 10 | 1.5S | 0 | 1 |

| Carbon steel | 2 | 16-20 | 3000 | N₂/Air | 10 | 2.0S | 0 | 0.5 |

| Carbon steel | 2 | 3.8-4.2 | 2100 | O₂ | 1.6 | 1.0D | +3 | 0.8 |

| Carbon steel | 3 | 3.2-3.6 | 2100 | O₂ | 0.6 | 1.0D | +4 | 0.8 |

| Carbon steel | 4 | 3-3.2 | 2400 | O₂ | 0.6 | 1.0D | +4 | 0.8 |

| Carbon steel | 5 | 2.7-3 | 3000 | O₂ | 0.6 | 1.2D | +4 | 0.8 |

| Carbon steel | 6 | 2.2-2.5 | 3000 | O₂ | 0.6 | 1.2D | +4 | 0.8 |

| Carbon steel | 8 | 1.8-2.2 | 3000 | O₂ | 0.6 | 1.2D | +4 | 0.8 |

| Carbon steel | 10 | 1-1.3 | 3000 | O₂ | 0.6 | 1.2D | +4 | 0.8 |

| Carbon steel | 12 | 0.9-1 | 2400 | O₂ | 0.6 | 3.0D | +4 | 0.8 |

| Carbon steel | 14 | 0.8-0.9 | 2400 | O₂ | 0.6 | 3.0D | +4 | 0.8 |

| Carbon steel | 16 | 0.6-0.7 | 2400 | O₂ | 0.6 | 3.5D | +4 | 0.8 |

| Carbon steel | 18 | 0.5-0.6 | 2400 | O₂ | 0.6 | 4.0D | +4 | 0.8 |

| Carbon steel | 20 | 0.4-0.55 | 2400 | O₂ | 0.6 | 4.0D | +4 | 0.8 |

| Carbon steel | 22 | 0.45-0.5 | 2400 | O₂ | 0.6 | 4.0D | +4 | 0.8 |

| Stainless steel | 1 | 28-35 | 3000 | N₂ | 10 | 1.5S | 0 | 0.8 |

| Stainless steel | 2 | 18-24 | 3000 | N₂ | 12 | 2.0S | 0 | 0.5 |

| Stainless steel | 3 | 7-10 | 3000 | N₂ | 12 | 2.5S | -0.5 | 0.5 |

| Stainless steel | 4 | 5-6.5 | 3000 | N₂ | 14 | 2.5S | -1.5 | 0.5 |

| Stainless steel | 5 | 3-3.6 | 3000 | N₂ | 14 | 3.0S | -2.5 | 0.5 |

| Stainless steel | 6 | 2-2.7 | 3000 | N₂ | 14 | 3.0S | -3 | 0.5 |

| Stainless steel | 8 | 1-1.2 | 3000 | N₂ | 16 | 3.5S | -4.5 | 0.5 |

| Stainless steel | 10 | 0.5-0.6 | 3000 | N₂ | 16 | 4.0S | -6 | 0.5 |

| Aluminum | 1 | 25-30 | 3000 | N₂ | 12 | 1.5S | 0 | 0.8 |

| Aluminum | 2 | 15-18 | 3000 | N₂ | 12 | 2.0S | 0 | 0.5 |

| Aluminum | 3 | 7-8 | 3000 | N₂ | 14 | 2.0S | -1 | 0.5 |

| Aluminum | 4 | 5-6 | 3000 | N₂ | 14 | 2.5S | -2 | 0.5 |

| Aluminum | 5 | 2.5-3 | 3000 | N₂ | 16 | 3.0S | -3 | 0.5 |

| Aluminum | 6 | 1.5-2 | 3000 | N₂ | 16 | 3.0S | -3.5 | 0.5 |

| Aluminum | 8 | 0.6-0.7 | 3000 | N₂ | 16 | 3.5S | -4 | 0.5 |

Note: The parameters marked in red in the table are only for samples production, which are greatly affected by various factors in actual processing. They are only suitable for small-scale production and are not recommended for large-scale production and processing. It is recommended to use higher power lasers if need to cut thicker materials.

Technical details

| Work area | 3000 x 1500mm |

| Laser power | 3000W (Raycus) |

| X-axis range | 1500mm |

| Y-axis range | 3000mm |

| Z-axis range | 100mm |

| Maximum positioning speed (XY) | 100m/min |

| Maximum positioning speed (total) | 100m/min |

| Positioning accuracy | ±0.02mm/m |

| Maximum acceleration | 1.3G |

| Positioning repeatability | ±0.03mm/m |

| Laser source | Raycus |

| Automatic lubrication | yes |

| Display | 21-inch vertical display |

| Control system | Raytools X3S |

| Beam | aluminum |

| Cutting head | Raytools BM110 Autofocus |

| Cooling | chiller |

| Gear racks | LEITESEN |

| Linear guides | PEK |

| Maximum table load capacity | 1500kg |

| Total machine weight | 3800kg |

| Dimensions | 5125x3975.8x2871.45mm |

Media