Spartus Apollo 700 laser cutting machine [6000W]

Available

Standard:

EN ISO 12100:2010

EN 60204-1:2018

EN ISO 11553-1:2020+A11:2020

Variants

Product description

SPARTUS APOLLO 700 LASER CUTTER – CUTTING PRECISION AT THE HIGHEST LEVEL

POWER, PRECISION AND PERFORMANCE

The SPARTUS Apollo 700 is an advanced laser cutter with 6 kW of power, combining outstanding cutting capabilities with top-tier build quality. Thanks to the fiber Raycus laser source and the intelligent Raytools BM06K cutting head, the machine delivers perfectly smooth edges even when cutting thick materials. The fast autofocus system and lens cooling ensure continuous, efficient operation.

INDUSTRY-READY DESIGN

At the heart of the machine is a reinforced frame welded from steel profiles, whose precision is ensured through multi-stage heat and mechanical processing. The crossbeam made from aerospace-grade aluminum offers exceptional rigidity and dynamic performance. The entire structure runs on PEK linear guides and high-precision racks from Atlanta and toothed racks Leitesen — trusted European brands.

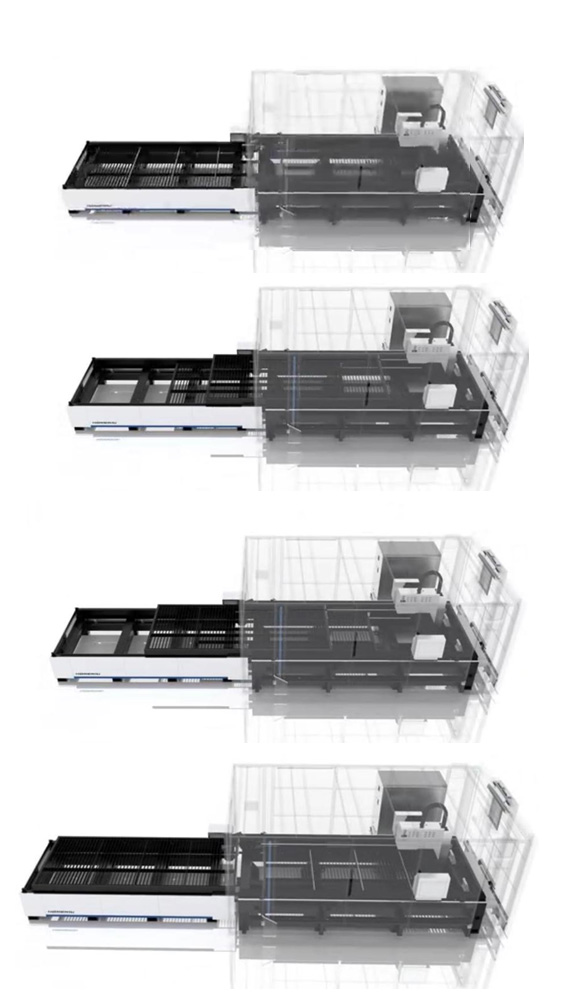

AUTOMATION THAT MAKES A DIFFERENCE

The automatic table exchange system allows uninterrupted cutting — the swap occurs in the background while the machine's axis returns to its home position, ensuring full operational safety.

PREMIUM-CLASS INTELLIGENT CUTTING HEAD

Raytools BM06K is more than just an autofocus head — it's a system featuring intelligent cooling, four protective lenses, and temperature monitoring. All data can be viewed in real time via a mobile app. This level of control protects the optics from overheating and contamination.

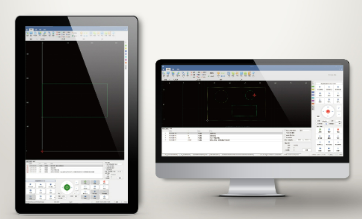

USER-ORIENTED CONTROL SYSTEM

Raytools X3S is an advanced control system that integrates design CAD, NEST, CAM and cutting parameterization into a single software. Users can automatically correct imported drawings, configure piercing points and micro joints, and monitor production statistics in detail.

VOLTAGE STABILIZER – POWER SUPPLY SAFETY AND RELIABILITY

The SPARTUS Apollo 700 cutter is equipped with a 80 kVA voltage stabilizer, which plays a key role in ensuring the machine’s safe and stable operation. The device automatically adjusts the power supply parameters to local energy conditions, regardless of the country or region. The voltage stabilization and regulation function protects electronic systems from surges and interference, increasing the durability of components and the overall reliability of the laser system.

ECOLOGY AND WORKPLACE SAFETY

The Apollo 700 has been designed with a clean working environment in mind. Its fully enclosed construction, sealed top cover, and zoned fume extraction system—combined with an optional filtration and ventilation unit—make it a user-friendly solution that meets occupational health and safety standards. Additionally, the internal camera system enables process monitoring without the need to open the protective covers.

PERFECT CUT QUALITY

The SPARTUS Apollo 700 delivers top-tier edge quality. With the optimal combination of laser power, intelligent control, and a high-rigidity structure, the machine meets the demands of even the most precision-focused industries.

- Glossy edges in carbon steel, free of burns and melt marks,

- Components with micro-holes and sharp corners cut without deformation,

- Perfect cut quality of various materials,

- Consistent cutting of thin-walled elements, with flawlessly smooth lines.

SPARTUS APOLLO 700 CUTTING PARAMETERS

| Material | Thickness [mm] | Cutting speed [m/min] | Laser power [W] | Gas | Pressure [bar] | Nozzle [mm] | Focus position [mm] | Cutting height [mm] |

|---|---|---|---|---|---|---|---|---|

| Carbon steel | 1 | 45-60 | 6000 | N₂/Air | 6.0 | 1.5S | 0.0 | 1.0 |

| Carbon steel | 2 | 35-40 | 6000 | N₂/Air | 6.0 | 2.0S | -1.0 | 0.5 |

| Carbon steel | 3 | 22-27 | 6000 | N₂/Air | 6.0 | 2.0S | -1.5 | 0.5 |

| Carbon steel | 4 | 15-20 | 6000 | N₂/Air | 8.0 | 2.0S | -2.0 | 0.5 |

| Carbon steel | 5 | 9-12 | 6000 | N₂/Air | 8.0 | 3.0S | -2.5 | 0.5 |

| Carbon steel | 6 | 8-10 | 6000 | N₂/Air | 8.0 | 3.5S | -3.0 | 0.5 |

| Carbon steel | 3 | 3.6-4.2 | 2400 | O₂ | 0.6 | 1.2E | 3.0 | 0.8 |

| Carbon steel | 4 | 3.2-3.4 | 2400 | O₂ | 0.6 | 1.2E | 3.0 | 0.8 |

| Carbon steel | 5 | 3-3.2 | 3000 | O₂ | 0.6 | 1.2E | 3.0 | 0.8 |

| Carbon steel | 6 | 2.7-2.9 | 3000 | O₂ | 0.6 | 1.2E | 3.0 | 0.8 |

| Carbon steel | 8 | 2.2-2.4 | 4500 | O₂ | 0.6 | 1.2E | 5.0 | 0.8 |

| Carbon steel | 10 | 2.0-2.2 | 6000 | O₂ | 0.6 | 1.2E | 7.0 | 0.8 |

| Carbon steel | 12 | 0.9-1 | 2400 | O₂ | 0.6 | 3.0D | 4.5 | 0.8 |

| Carbon steel | 12 | 1.9-2.1 | 6000 | O₂ | 0.6 | 1.2E | 9.0 | 0.8 |

| Carbon steel | 14 | 0.8-0.9 | 2400 | O₂ | 0.6 | 3.5D | 5.0 | 0.8 |

| Carbon steel | 14 | 1.4-1.6 | 6000 | O₂ | 0.6 | 1.4E | 12.0 | 0.8 |

| Carbon steel | 16 | 0.7-0.8 | 2400 | O₂ | 0.6 | 4.0D | 5.5 | 0.8 |

| Carbon steel | 16 | 1.2-1.4 | 6000 | O₂ | 0.6 | 1.4E | 13.0 | 0.8 |

| Carbon steel | 18 | 0.55-0.65 | 2400 | O₂ | 0.6 | 4.0D | 5.5 | 0.8 |

| Carbon steel | 18 | 0.8 | 6000 | O₂ | 0.6 | 1.4E | 13.0 | 0.3 |

| Carbon steel | 20 | 0.5-0.6 | 2400 | O₂ | 0.6 | 4.0D | 5.5 | 0.8 |

| Carbon steel | 20 | 0.6-0.8 | 6000 | O₂ | 0.75 | 1.4E | 13.5 | 0.3 |

| Carbon steel | 22 | 0.45-0.5 | 2400 | O₂ | 0.6 | 4.5D | 5.5 | 0.8 |

| Carbon steel | 22 | 0.5-0.6 | 6000 | O₂ | 0.75 | 1.5S | 13.5 | 0.3 |

| Carbon steel | 25 | 0.55 | 2700 | O₂ | 0.6 | 5.0D | 5.5 | 0.8 |

| Carbon steel | 25 | 0.4-0.5 | 6000 | O₂ | 0.75 | 1.5S | 14.0 | 0.3 |

| Carbon steel | 30 | 0.3 | 6000 | O₂ | 1.0 | 1.5S | 14.0 | 0.3 |

| Stainless steel | 1 | 45-60 | 6000 | N₂ | 10.0 | 1.5S | 0.0 | 0.8 |

| Stainless steel | 2 | 35-45 | 6000 | N₂ | 12.0 | 2.0S | -1.0 | 0.5 |

| Stainless steel | 3 | 22-27 | 6000 | N₂ | 12.0 | 2.5S | -1.5 | 0.5 |

| Stainless steel | 4 | 15-20 | 6000 | N₂ | 14.0 | 2.5S | -2.0 | 0.5 |

| Stainless steel | 5 | 9-12 | 6000 | N₂ | 14.0 | 3.0S | -2.5 | 0.5 |

| Stainless steel | 6 | 8-11 | 6000 | N₂ | 15.0 | 3.0S | -3.0 | 0.5 |

| Stainless steel | 8 | 3.5-4.5 | 6000 | N₂ | 15.0 | 3.0S | -4.0 | 0.5 |

| Stainless steel | 10 | 2-2.5 | 6000 | N₂ | 15.0 | 3.5S | -6.0 | 0.5 |

| Stainless steel | 12 | 1.5-1.8 | 6000 | N₂ | 16.0 | 3.5S | -7.5 | 0.5 |

| Stainless steel | 14 | 1-1.5 | 6000 | N₂ | 16.0 | 4.0S | -9.0 | 0.5 |

| Stainless steel | 16 | 0.5-0.6 | 6000 | N₂ | 18.0 | 4.0S | -14.0 | 0.5 |

| Stainless steel | 18 | 0.3-0.5 | 6000 | N₂ | 20.0 | 5.0S | -15.0 | 0.3 |

| Stainless steel | 20 | 0.2-0.25 | 6000 | N₂ | 20.0 | 5.0S | -16.0 | 0.3 |

| Aluminium Alloy | 1 | 45-60 | 6000 | N₂ | 12.0 | 1.5S | 0.0 | 1.0 |

| Aluminium Alloy | 2 | 35-40 | 6000 | N₂ | 12.0 | 2.0S | -1.0 | 0.5 |

| Aluminium Alloy | 3 | 22-27 | 6000 | N₂ | 14.0 | 2.5S | -1.5 | 0.5 |

| Aluminium Alloy | 4 | 14-17 | 6000 | N₂ | 14.0 | 2.5S | -2.0 | 0.5 |

| Aluminium Alloy | 5 | 9-11 | 6000 | N₂ | 14.0 | 3.0S | -3.0 | 0.5 |

| Aluminium Alloy | 6 | 4-6 | 6000 | N₂ | 16.0 | 3.0S | -3.0 | 0.5 |

| Aluminium Alloy | 8 | 2.5-3 | 6000 | N₂ | 16.0 | 3.0S | -7.0 | 0.5 |

| Aluminium Alloy | 10 | 1.5-1.8 | 6000 | N₂ | 18.0 | 3.5S | -8.0 | 0.5 |

| Aluminium Alloy | 12 | 0.8-1 | 6000 | N₂ | 18.0 | 4.0S | -8.0 | 0.5 |

| Aluminium Alloy | 14 | 0.6-0.7 | 6000 | N₂ | 18.0 | 4.0S | -9.0 | 0.3 |

| Aluminium Alloy | 16 | 0.35-0.45 | 6000 | N₂ | 20.0 | 5.0S | -12.0 | 0.3 |

| Aluminium Alloy | 20 | 0.2-0.3 | 6000 | N₂ | 20.0 | 5.0S | -13.0 | 0.3 |

| Note: The parameters marked in red in the table are only for samples production, which are greatly affected by various factors in actual processing. They are only suitable for small-scale production and are not recommended for large-scale production and processing. It is recommended to use higher power lasers if need to cut thicker materials. | ||||||||

Technical details

| Work area | 3050 x 1520mm |

| Laser power | 6000W (Raycus) |

| X-axis range | 1520mm |

| Y-axis range | 3050mm |

| Z-axis range | 300mm |

| Maximum positioning speed (XY) | 100m/min |

| Maximum positioning speed (total) | 120m/min |

| Positioning accuracy | ±0.02mm/m |

| Maximum acceleration | 1.3G |

| Positioning repeatability | ±0.03mm/m |

| Laser source | Raycus |

| Automatic lubrication | yes |

| Display | 27-inch vertical screen |

| Control system | Raytools X3S |

| Beam | aluminum |

| Cutting head | Raytools BM06K Autofocus |

| Cooling | chiller |

| Gear racks | LEITESEN |

| Linear guides | PEK |

| Maximum table load capacity | 2150kg |

| Total machine weight | 6000kg |

| Dimensions | 9687x2970x2323mm |

Media