SPARTUS Easy 2000 laser welding machine with double wire feeder

Out of stock in the main warehouse, does not take into account distributor's stock levels

Notify me about availability

The set includes:

- laser source Raycus

- F280 handheld laser head (9,5m) with F150 focus lens

- double wire feeder with 4 wire guide rollers 1.2 - 1.6V fi37

- distilled water or coolant – selection depending on the season

- single insulated steel liner

- double insulated steel liner

- 2 wire guide rollers 0.8 - 1.0V fi37

- 4 wire guide rollers 2.0 -2.5V fi37

- head support for double liner

- 6 double welding nozzles

- 3 double wire feeder tip

- set of single nozzles for the laser head

- 4 single wire feeder tips

- protective lenses

Variants

Product description

SPARTUS EASY 2000 laser welder – INNOVATIVE TECHNOLOGY FOR JOINING, CUTTING AND CLEANING MATERIALS

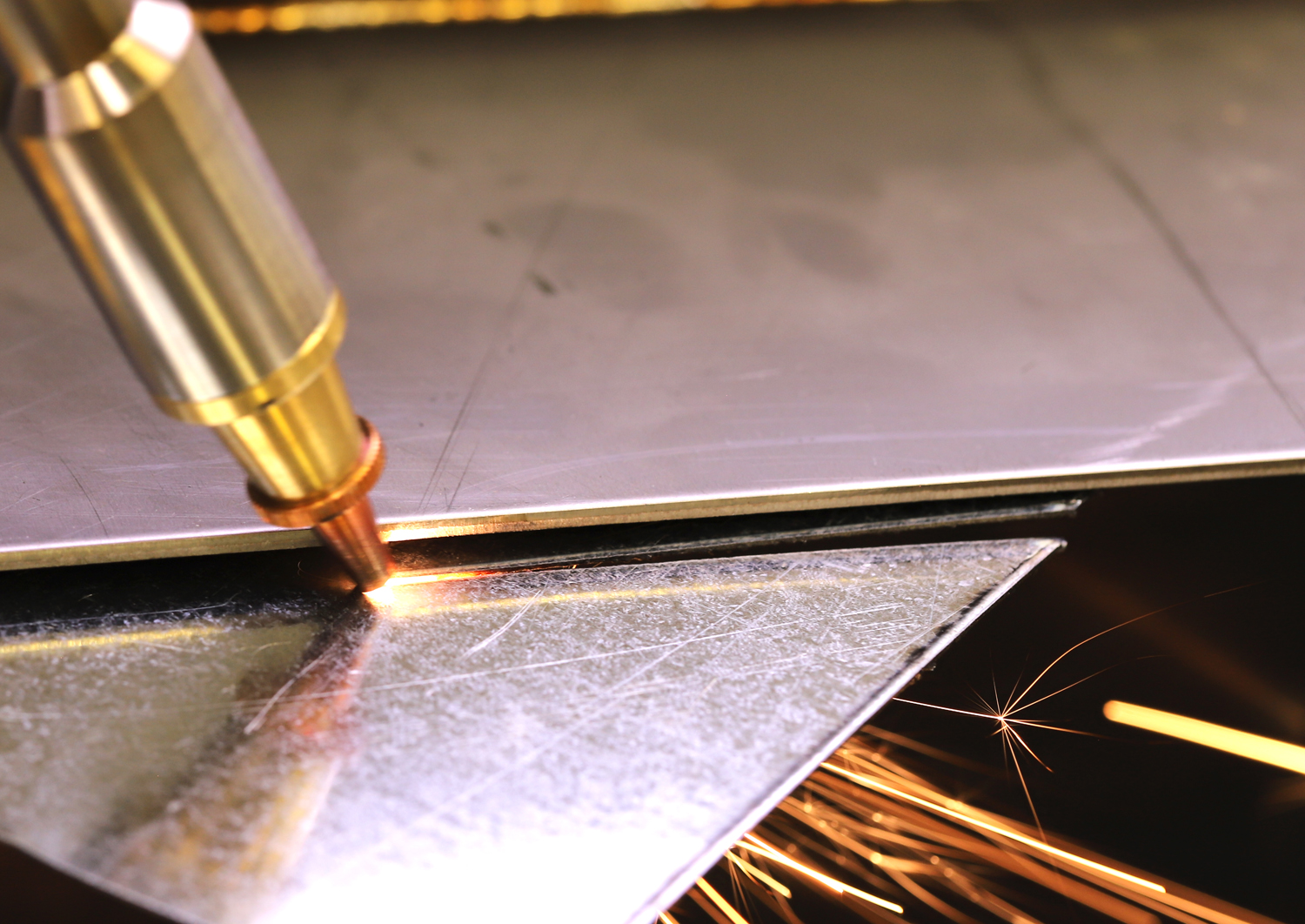

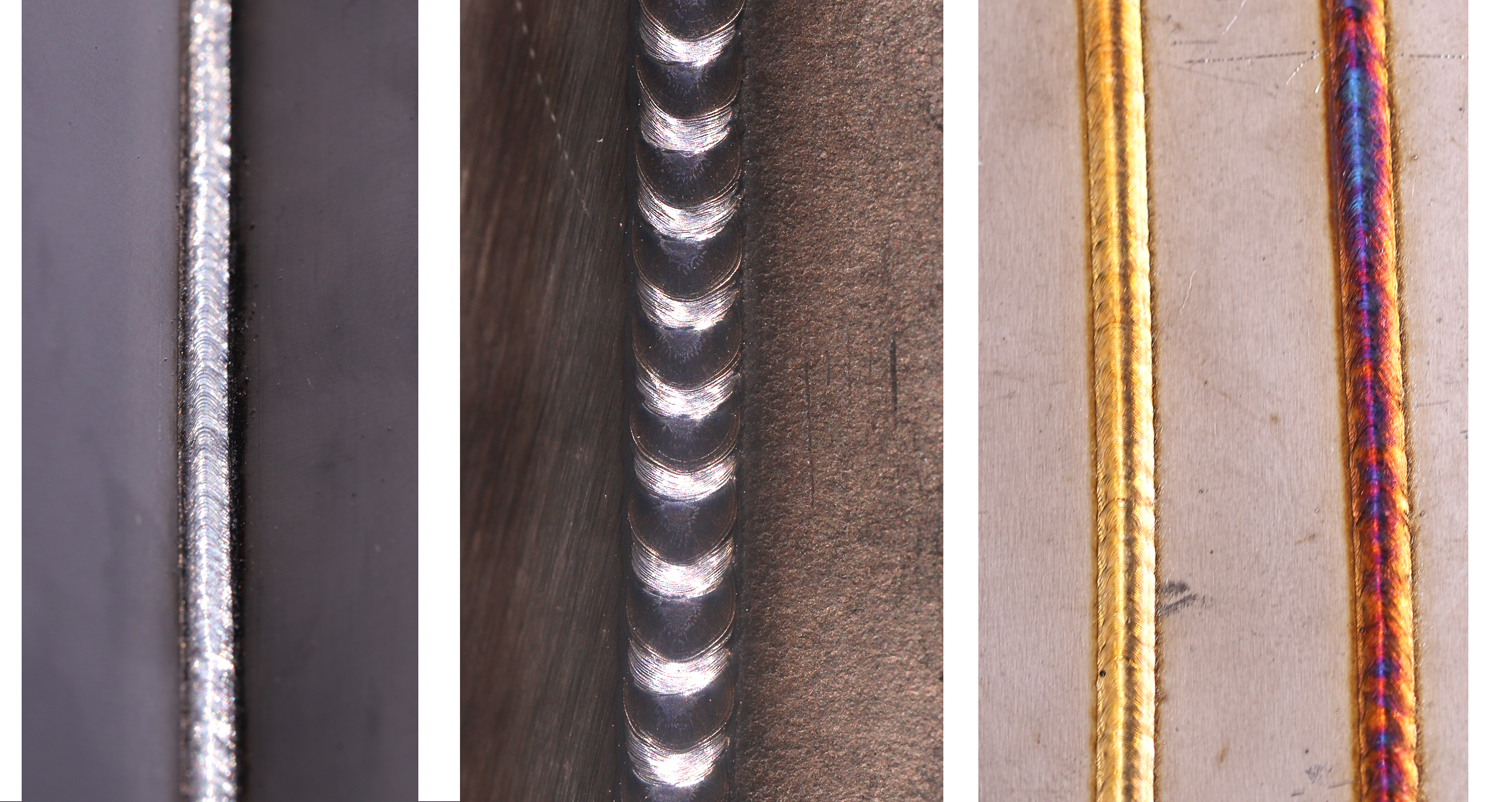

SPARTUS Easy 2000 laser welder is the key to achieving welds of unmatched quality. The device outperforms traditional welding methods such as MIG or TIG due to the exceptional precision it offers. Laser welding allows for much smaller, microscopic welds, which minimizes the heat-affected zone on the surrounding material. This makes laser welding an excellent choice for joining even very small components that are difficult to weld using other methods.

Advantages of the SPARTUS Easy 2000 laser welder:

- high welding precision

- excellent control over the welding process

- minimal material distortion

- clean welds with no need for finishing

- suitable for hard-to-reach areas

- optimized production time

- durable and strong joints

- ability to weld, cut, and clean various materials

- high-quality laser source

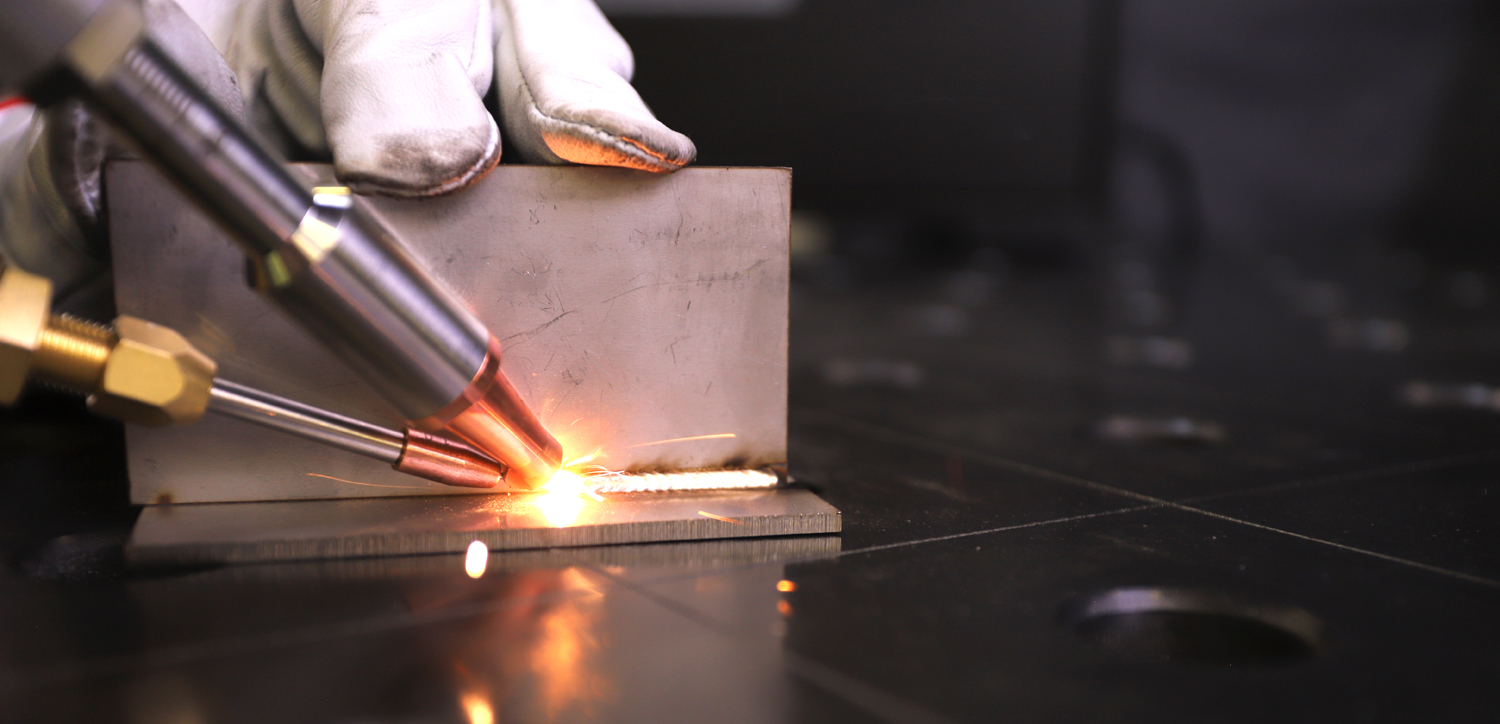

DUAL WIRE FEEDER

The SPARTUS® dual wire feeder was designed to improve the efficiency and quality of welding processes in the most demanding industrial environments. Its innovative design allows for the use of two welding wires. The SPARTUS® dual wire feeder offers:

- INCREASED PRODUCTIVITY – reduces downtime related to spool changes, boosting production cycle efficiency.

- VERSATILITY – quickly adapts to changing project requirements.

- PROCESS OPTIMIZATION – easily switch between wires of different diameters or properties to suit specific tasks, ensuring high-quality welds and work efficiency.

- IMPROVED WELD QUALITY – allows better fit for larger gaps, resulting in stronger and more aesthetic welds.

- REDUCED OPERATING COSTS – long-term savings through reduced downtime and improved efficiency.

WELDABLE MATERIALS

Maximum material thickness:

Stainless steel: 6.5mm

Galvanized sheet: 5mm

Iron: 6mm

Mild steel: 6mm

Aluminum: 5mm

Brass: 3mm

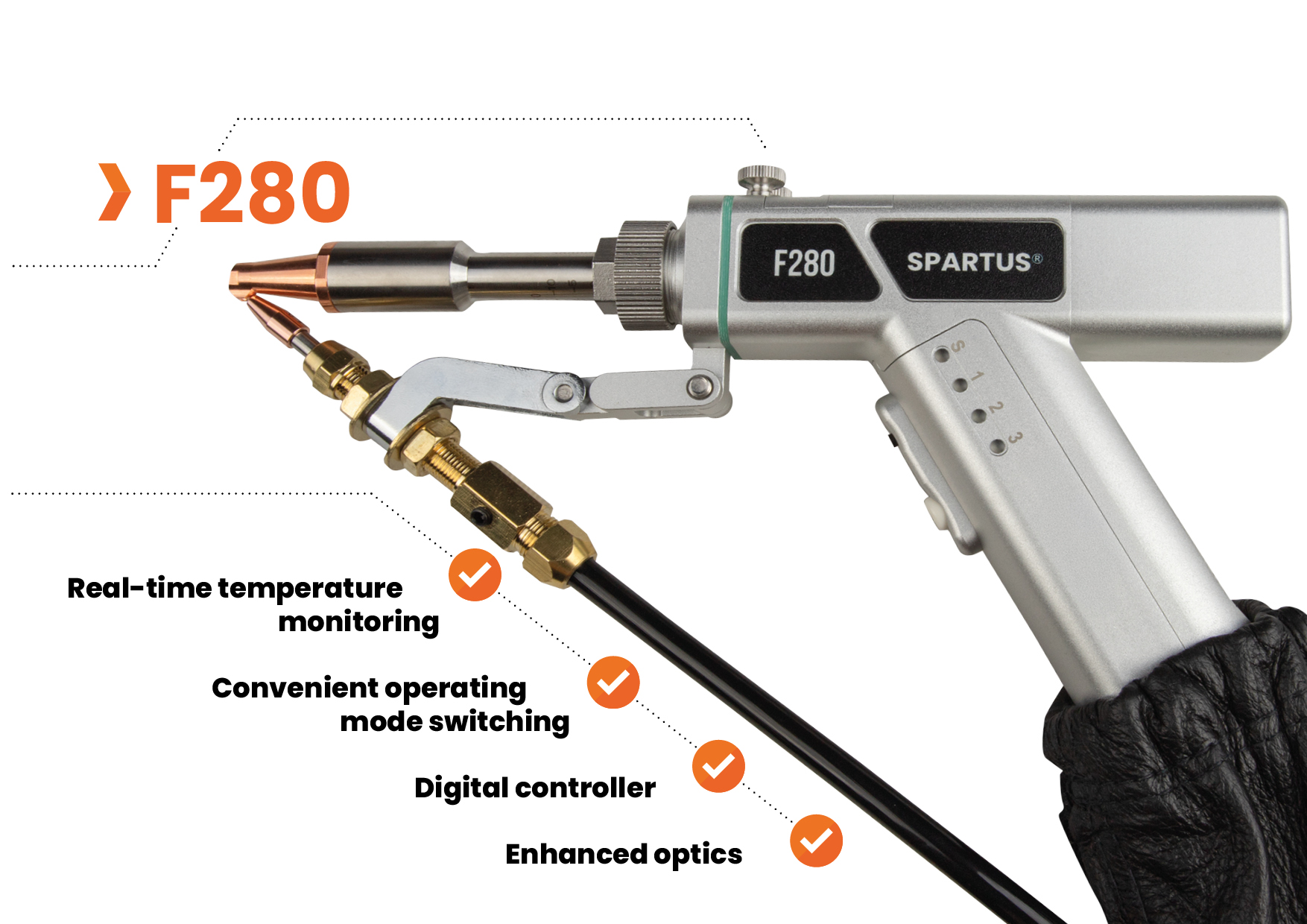

SPARTUS F280 LASER HEAD – PRECISION, RELIABILITY AND CONTROL

The F280 laser head features an advanced real-time temperature monitoring system. A flashing red light indicates overheating, while a steady light signals other alarms, providing full control over device operation.

An independent mode switch button enables quick and convenient switching between preset processes. The digital controller ensures high resistance to interference and stable, reliable performance in any conditions.

Thanks to the improved optical design, the head delivers high-quality welds, minimal distortion, and deep penetration, resulting in excellent welding results.

ONE DEVICE – MANY FUNCTIONS

SPARTUS® Easy 2000 is designed not only for welding but also for cutting and cleaning various materials.

Laser cutting enables precise separation of materials, producing clean and accurate edges without mechanical processing. As an additional option, the cutting function allows cutting stainless steel up to 2mm and carbon steel up to 1.5mm. Due to their high reflectivity, copper and aluminum should not be laser cut.

Laser cleaning is an effective method for removing contaminants, paint layers, or rust from surfaces while maintaining their quality and integrity. These laser applications provide outstanding efficiency in material processing with minimal impact on structure.

MULTILINGUAL MENU

The interface is available in the following languages: • Polish • English • German • French • Spanish • Italian • Czech • Slovak • Greek • Romanian • Portuguese • Korean • Turkish • Russian

Technical details

| Input | ~1× 230V ± 10% 50 / 60 Hz |

| Output power | 2000W |

| Operating mode | continuous / modulation |

| Cooling type | liquid |

| Duty cycle | 100% |

| Scanning speed | 2 - 6000 mm/s |

| Scanning width | 0 - 8 mm |

| Frequency | 5 - 5000 Hz |

| Weight | 165kg |

| Dimensions | 956 × 580 × 823 mm |